Guard Against Electric Shock from Leakage Current in Power Supplies

When designing a PC-based medical device, you need a reliable energy source that won’t shock patients. Minimizing leakage current, a leading potential cause of shock hazard is an important part of your device design and vitally important in medical power supplies.

At all times you should avoid shock hazards in your designs, but it’s most important with medical devices. They could be near or touching patients who are already vulnerable to existing medical conditions. They may also not be mobile enough or aware enough to move away from the source of an electric shock.

In PC-based medical devices, the power supply is one of the primary places to reduce leakage current, which is a common cause of shock hazards. As covered in the previous post, there are three types of leakage current in medical devices — earth, touch, and patient. Patient leakage current is mitigated by the device enclosure, which encases the power supply. Power supply design therefore focuses on minimizing earth and touch leakage current.

What causes leakage current in power supplies?

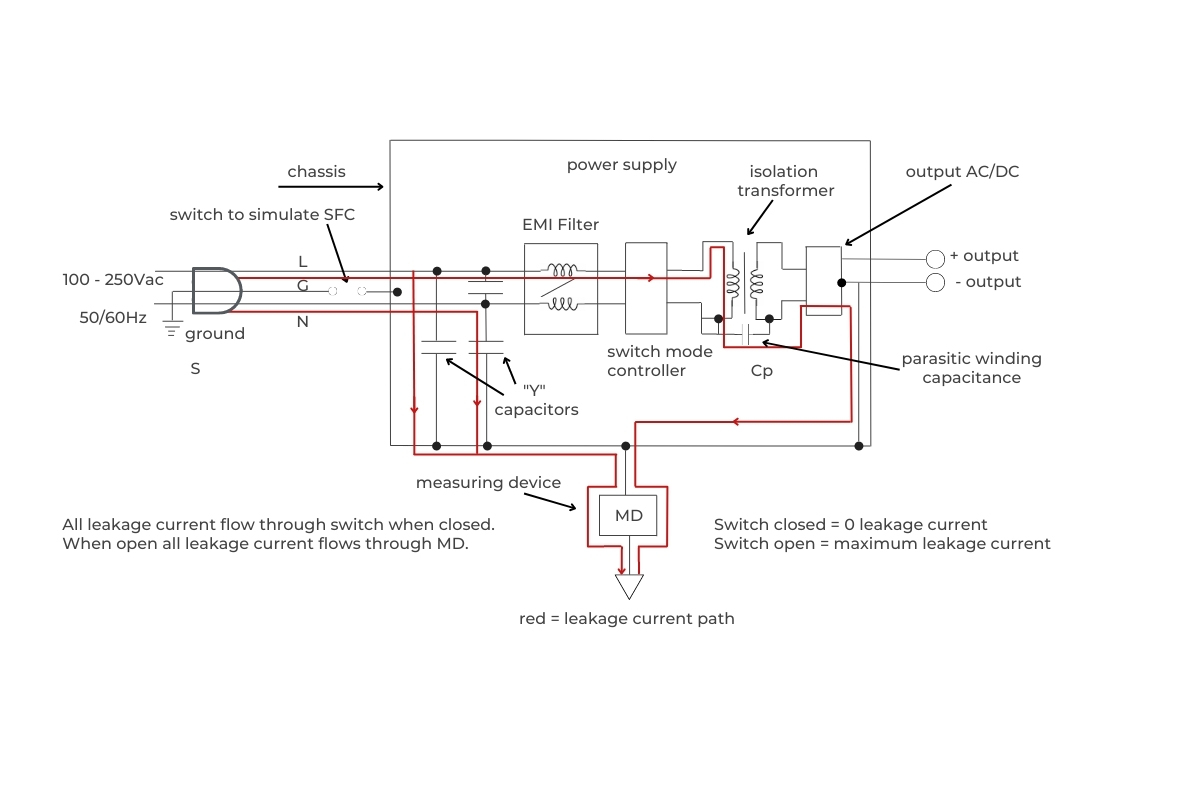

Leakage current can be found in any electrical device or system that’s run by AC power, including a PC-based power supply (PSU). The unwanted current could come from several sources, but the most common path is through the Y-class EMI filter capacitors to the ground.

A trade-off between leakage and EMI

Y capacitors are often the cause of leakage current in a power supply. They can mitigate EMI, but they can also hold a charge. Increase the capacitance and you raise the amount of leakage current while lowering the EMI, or vice versa. Neither leakage current nor EMI is desirable. Medical device standards regulate both. Manufacturers have to put on a balancing act to mitigate each to the proper degree.

What is EMI?

Electromagnetic interference (EMI) is electrical noise. It is an unwanted byproduct when switching currents and voltages. EMI is unavoidable in a switching power supply and it can cause problems with other devices by interfering with electrical signals. EMI filtering is needed and usually done using Y-class safety capacitors.

What are Y Capacitors?

Y-class safety capacitors (also called Y capacitors) are used to suppress the EMI generated by the power supply. They are placed between the AC line and the ground on the primary side of the power supply.

How do Commercial and Medical Power Supplies Differ?

All power supplies provide safety features. However, medical-grade power supplies must meet rigorous Means of Protection (MOP) standards for earth and touch leakage current to protect vulnerable patients. Commercial-grade power supplies can have up to twenty times the leakage current as those certified as medical-grade.

When designing a PC-based medical device, you need a reliable energy source that won’t shock patients. Minimizing leakage current, a leading potential cause of shock hazard, is an important part of your device design and vitally important in medical power supplies.

For further information, please see our articles “Medical-Grade Power Supplies: Safety and Reliability Set Them Apart” and “Electrical Safety in PC Based Medical Products” or contact us.

(Leakage Current in Medical Devices, Leakage Current in Power Supplies, Leakage Current Requirements for Medical Power Supplies)

________________________

RAM Technologies power supplies are designed to meet medical device requirements, keeping both SFC leakage current and conducted noise to a minimum and meeting 2XMOPP patient protection standards.