Mean Time Between Failures (MTBF)

What is MTBF?

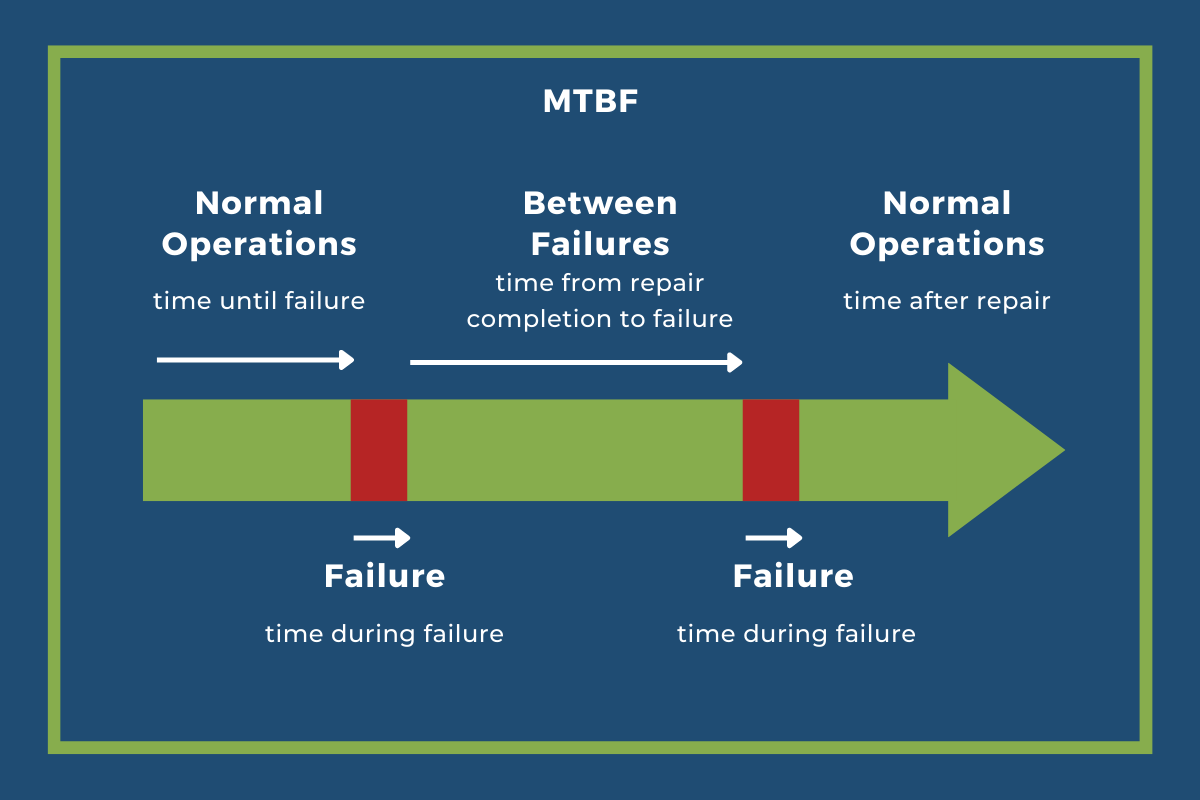

MTBF stands for Mean Time Between Failures. It is a metric to measure the reliability of a product.

- The mean is the average time, or arithmetic mean, between repairable product failures

- The measured time is during normal operation (uptime) of a product that is repairable

- Failures are conditions that render the product out of specification for normal use and in need of repair (downtime). This does not include downtime due to a system shutdown or routine maintenance.

Why measure MTBF?

MTBF is a useful indicator of product reliability. The higher the MTBF number, the longer a product is expected to work under normal operating conditions before it needs to be serviced or replaced. It is useful, but not an exact predictor. Failures can also occur as a reaction to environmental factors, or as a reaction to a failure in another part of the system.

How is mean time between failures calculated?

To calculate the MTBF of a product:

- Select a specific timespan.

- Count the total amount of time that the product is operational (its uptime).

- Count the number of failures (downtime). Do not include scheduled routine maintenance downtime as a failure (that is, downtime that is part of the product design parameters).

- Divide the operational time by the number of failures.

For example, say you have a device that is designed to run for 10 hours per day. After operating for five days, it breaks down. It was operational for 50 hours.

(10 hours per day * 5 days) / 1 failure = MTBF of 50 hours

Of course, you can get a better sense of general product reliability by calculating the average of the MTBF of a statistically significant number of products, within a specific timespan and environmental conditions.

Other Metrics – What’s in a Letter?

When looking at specifications, make sure you don’t get all the acronyms confused. There are other metrics that look similar to mean time between failures, but stand for something distinct.

DMTBF

DMTBF stands for Demonstrated Mean Time Between Failures. It might take weeks or years for a product failure to occur in the field. To get results sooner, MTBF might be arrived at by simulating the longer timespan. This may include using various calculations, like the known MTBF of components (capacitors, for example) under specific conditions or by putting the product under controlled stress conditions designed to speed up failure rates.

Just as it sounds, Demonstrated MTBF is based on actual recorded product failures in normal operating conditions and over actual time. Some calculations are still called for if, for example, the products are not in a controlled environment and not operating for a specified number of hours per day. If there is a low number of products recorded, statistical tools might be used to calculate the DMTBF.

MTTF

MTTF stands for Mean Time to Failure. While MTBF is used to measure uptimes between failures in repairable products, for products that must be replaced instead of repaired (like a lightbulb), use Mean Time to Failure. MTTF is equivalent to the operating lifespan of the product. Like MTBF, when you track a large number of the same product for a specified time, noting their failure times and dividing that time by the number of products counted, you get a good indicator of how long you could expect your product to last in normal operating conditions.

MTTR

MTTR stands for Mean Time to Repair. It is a measure of the time it takes to fix a failure after it has been detected until it is returned to normal operation. This is the total repair downtime, whereas MTBF is a measure of uptime.

MultiLoop Technology and Mean Time Between Failures

At the core of RAM Technologies’ power supplies is the exclusive MultiLoop Technology, which uses high-efficiency voltage converters. MultiLoop Technology boosts power output and eliminates single-loop cross-regulation errors while dramatically reducing component heat stress. The result is very stable high-power outputs and an extremely high MTBF.

Most “medical” PC power supplies are just certified to medical standards, but their design is still for the commercial PC market, which typically is designed to have an MTBF of 100,000 to 200,000 hours. RAM Technologies power supplies have a Demonstrated MTBF of much greater than 500,000 hours. We accomplish this high MTBF through careful design and by using the highest-quality components available.

________________________

RAM medical power supplies have a Demonstrated MTBF of well over 500,000 hours. Contact us for details.